How does the whistle on your oil tank work, and what does it have to do with getting your tank filled? We will explain these answers so that you know exactly how we fill your tank during an oil delivery.

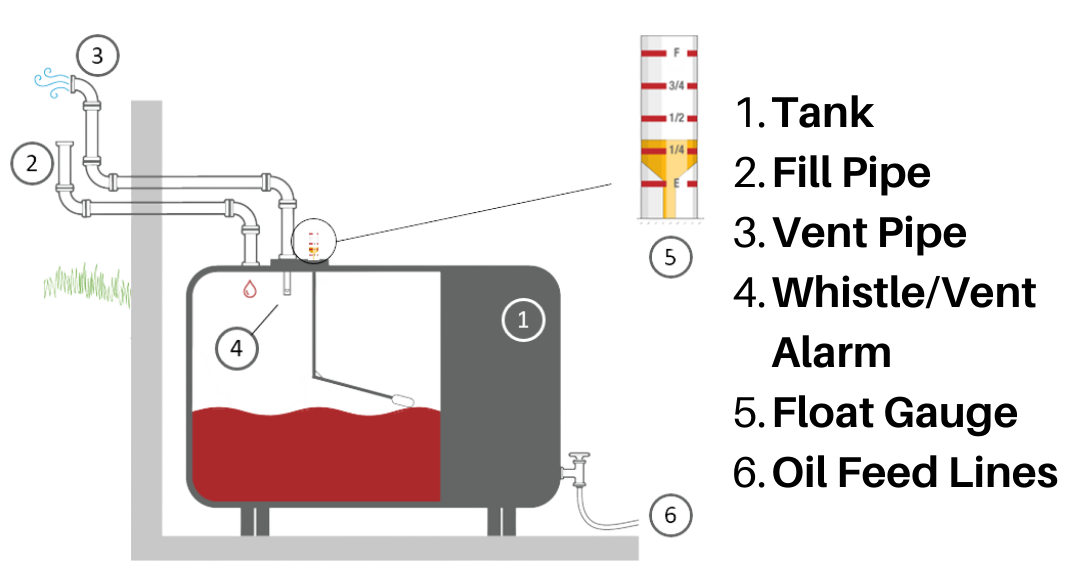

A whistling sound that occurs when your tank is being filled with oil is a sign that the tank is in good working order. The whistle is usually found in the vent pipe just above the tank. As oil is being pumped into the tank, it displaces the air. This air comes out of the vent pipe and is what blows the whistle. When the tank is full the whistle stops blowing. This is what helps the person that is filling the tank to put just enough and to avoid overfilling the tank. Again, having a functioning whistle on your oil tank is important in preventing overflow and damage to your home/the environment.

It's so important, in fact, that many companies will not fill your tank if there's no whistle or if the whistle is broken, as they do not want to risk an oil spill.

A good way to picture how it works is like soda being poured into a glass. As you pour the soda, it rapidly bubbles and foams up, making it seem higher than it actually is. Before you can pour more soda in, you have to wait for the bubbles to dissipate. Once the bubbles are gone, you know that you can fill the glass with more soda. If you had continued pouring before the foam went away, the soda would overflow and there would be a mess.

The same goes for your oil tank! If you were to top off the tank before the vapors and foam went down, your tank could overfill and cause many issues.

At ECI Comfort / My Express Oil, our goal is to provide our customers with safe, clean deliveries. Our policy for safe oil fills at ECI/MEO goes by the same logic as above. We fill the tank until the whistle stops. Once the whistle stops the first time, we wait a little bit as the oil can bubble up and prematurely stop the whistle. We then slowly start to reopen the nozzle into the fill pipe and see how the whistle reacts. If it starts to sound again, we will continue on slow until it stops a second time, then we will turn it off, and voila -- your tank is filled to capacity.

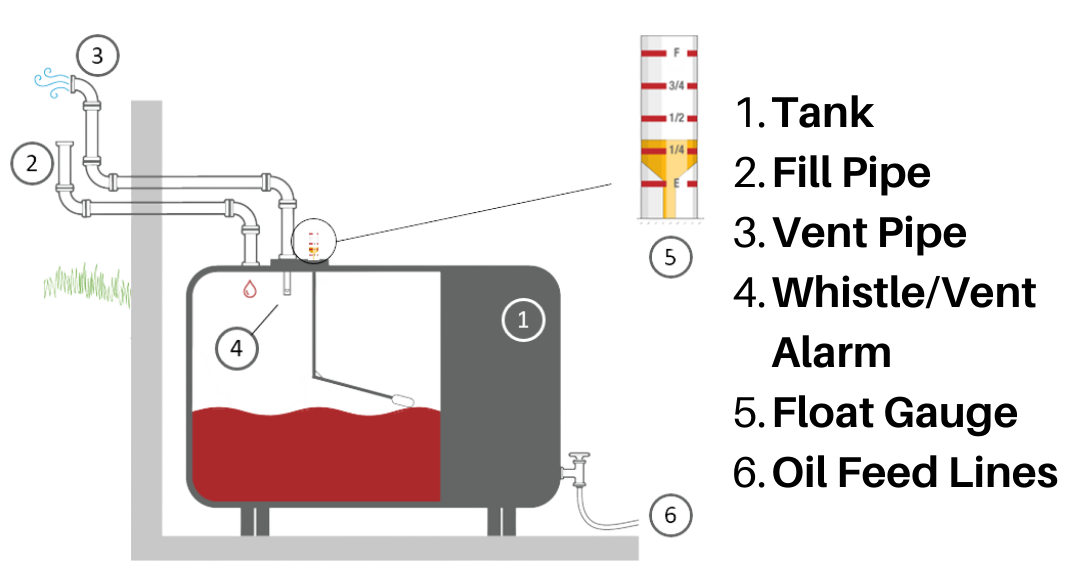

On the other hand, if we slowly reopen the nozzle and the whistle still doesn't sound, we know that the tank was at capacity the first time. If you check your oil gauge and see that it's not 100% full, it's because we also leave a small gap in case the oil expands due to warmer temperatures.

Have any questions or would like to schedule an oil delivery? Give us a call at 215-245-3200 or order online.