Without a properly functioning compressor, an AC system would be unable to cool the air efficiently, leading to a decline in performance and comfort. In this blog post, we will discuss three common reasons why compressors fail and explore the importance of proper maintenance, electrical system issues, and refrigerant-related problems.

How Does an AC Compressor Work?

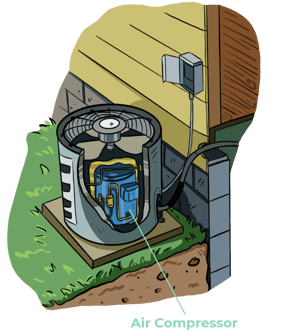

The compressor serves as the heart of the cooling process by compressing the refrigerant gas, to increase its pressure and temperature. The compressed refrigerant then flows through the system, releasing heat and cooling down as it passes through the condenser coils. The cooled and condensed refrigerant circulates through the evaporator coils, absorbing heat from the indoor air and effectively cooling it. By continuously compressing and circulating the refrigerant, the compressor enables the AC system to regulate temperature and provide refreshing cool air to the indoor space.

The compressor serves as the heart of the cooling process by compressing the refrigerant gas, to increase its pressure and temperature. The compressed refrigerant then flows through the system, releasing heat and cooling down as it passes through the condenser coils. The cooled and condensed refrigerant circulates through the evaporator coils, absorbing heat from the indoor air and effectively cooling it. By continuously compressing and circulating the refrigerant, the compressor enables the AC system to regulate temperature and provide refreshing cool air to the indoor space.3 Reasons Your AC Compressor May Not Be Working

1. Lack of proper maintenance

One of the primary reasons compressors fail is a lack of regular maintenance. Over time, compressors accumulate dirt, debris, and contaminants, which can clog filters, reduce lubrication effectiveness, and hinder the overall performance of the unit. Insufficient lubrication can cause increased friction and heat buildup, leading to premature wear and tear. Failure to clean or replace air filters regularly can also result in reduced airflow, causing the compressor to work harder, increasing the risk of failure.

To prevent compressor failure due to inadequate maintenance, it is crucial to establish a regular maintenance schedule. This includes cleaning or replacing filters, inspecting and lubricating moving parts, checking for refrigerant leaks, and ensuring proper electrical connections. By investing in annual maintenance, you can extend the lifespan of your compressor and minimize the risk of unexpected breakdowns.

2. Electrical issues

Electrical problems can significantly impact the performance and reliability of compressors. Issues such as voltage fluctuations, inadequate power supply, or faulty electrical connections can cause the compressor to fail. For instance, low voltage can lead to insufficient torque, resulting in the compressor struggling to start or operating at reduced efficiency. Similarly, power surges or electrical spikes can damage sensitive components within the compressor, leading to catastrophic failures.

To mitigate electrical issues, it is crucial to ensure that the compressor is connected to a stable power supply that meets the required voltage and current specifications. Consider using surge protectors or voltage regulators to safeguard against electrical fluctuations. Additionally, regular inspection of electrical connections and wiring can help identify and address any potential issues before they cause compressor failure.

3. Refrigerant issues

Refrigerant-related problems can also contribute to compressor failure. Refrigerant is responsible for absorbing heat and facilitating the cooling process within the compressor. Insufficient refrigerant levels due to leaks or improper charging can cause the compressor to overheat, leading to system failure. Moreover, the presence of contaminants or moisture in the refrigerant can corrode the compressor's internal components, reducing its efficiency and eventually causing a breakdown.

To prevent refrigerant-related compressor failures, it is essential to regularly inspect the refrigerant lines for leaks and promptly address any detected issues. Additionally, proper refrigerant charging procedures should be followed to ensure the optimal level of refrigerant in the system. Maintaining clean and moisture-free refrigerant through appropriate filtration and drying techniques can also help preserve the compressor's integrity.

Conclusion

Understanding the common reasons why compressors fail is crucial for ensuring their longevity and reliable operation. Lack of proper maintenance, electrical issues, and refrigerant-related problems are among the leading causes of compressor failure. By implementing regular maintenance routines, addressing electrical system concerns, and maintaining optimal refrigerant levels, you can significantly reduce the risk of compressor failure and avoid costly repairs or replacements. Remember, proactive care and attention to these key areas will go a long way in keeping your compressor running smoothly for years to come.

If you live in the Delaware Valley/Greater Philadelphia area and would like to find comfort within your home, visit our website or give us a call at 215 - 245 - 3200 to learn more.